Load Pull Verification

Opportunity Statement

SSR load accuracy to reduce inventory variance.

Defect

Pulling loads with no verification between warehouse partners.

Goal Statement

Create a load pull verification process with an error metric system.

Solution

Implement a multi-factor authentication process between warehouse partners, SSRs, and serice managers.

-

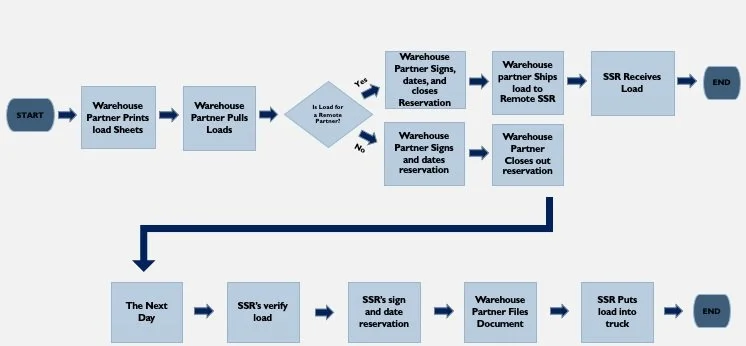

WH partner 1 pulls loads and places load in designated area after signing off on reservation sheet.

WH partner 2 thoroughly verifies the load and initials off on reservations sheet next to items. WH partner 2 will then place verified load into designated SSR pickup zone.

WH Partner 2 closes out reservation.

Next day, both WH partners verify loads with SSRs. After loads are verified, SSRs sign off on reservation sheet and take loads to truck.

-

WH partner 1 pulls loads and places load in designated area after signing off on reservation sheet.

WH partner 2 thoroughly verifies the load and initials off on reservations sheet next to items.

Service Manager does final verification of load before items are packaged and shipped to remote SSR.

WH Partner 2 closes reservation.

WH Partner 1 packages items and ships to remote SSR.

Implementation Plan

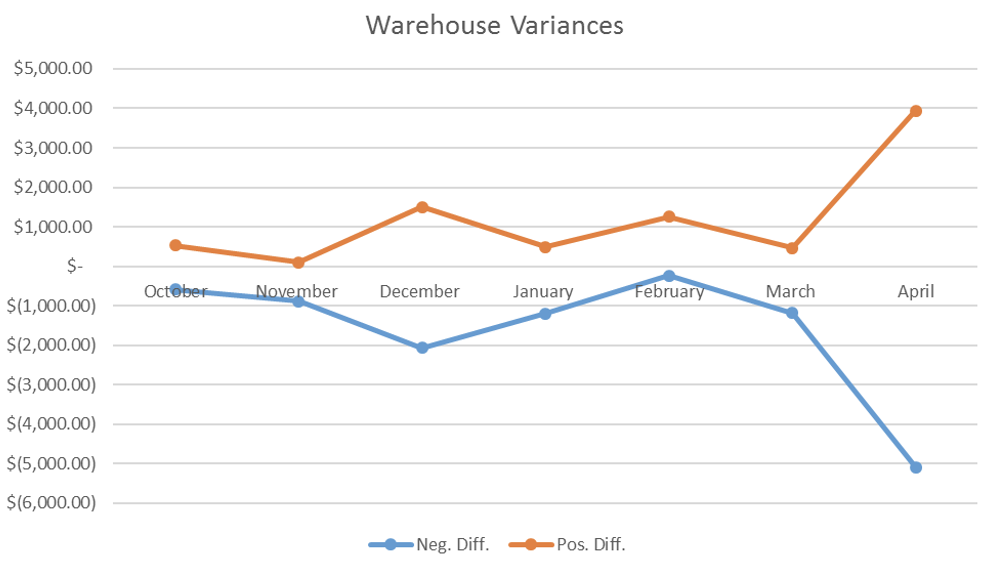

Total Variance $19,517.18

The Data provides insight on both significant variances on both the positive and negative side. With a total of almost $3000 dollars lost due to variance in inventory in the last 6 months. If we look at it in total variance we see a almost a total of $20,000 (total plus and minus difference)

-

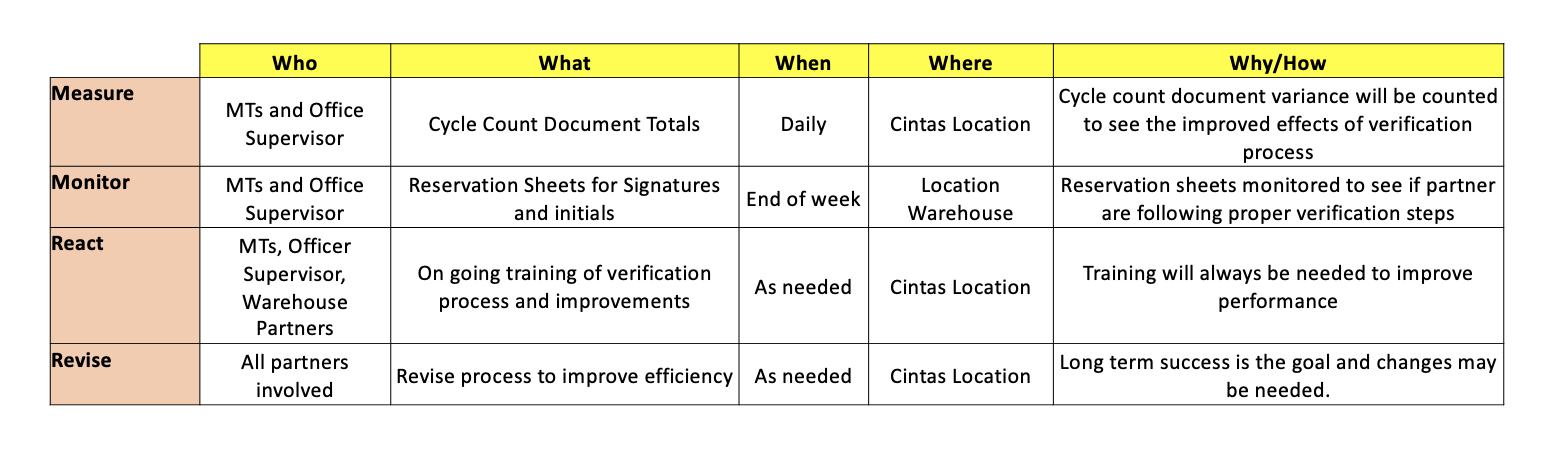

Detailed Process Map

-

New Process Map

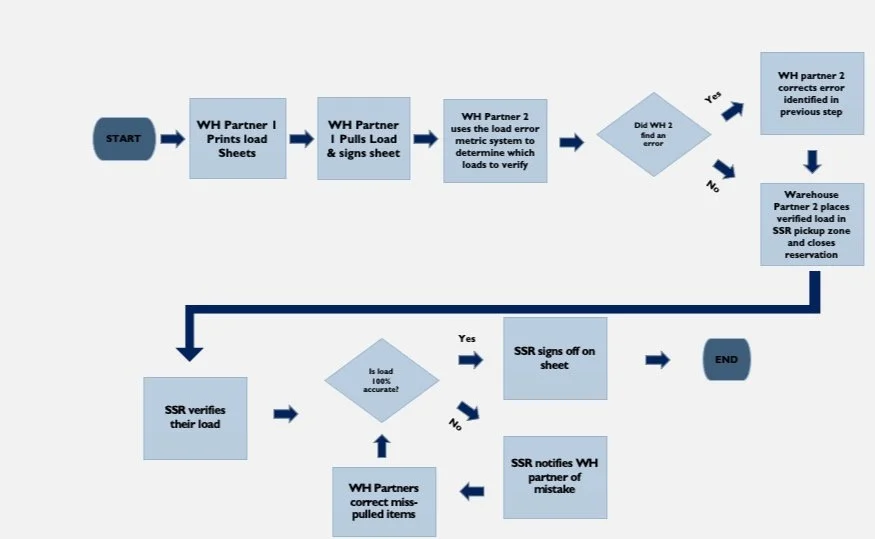

Change Management

The whole location is going to be impacted, however, warehouse will definitely see the change. We will discuss the data we gathered and mention the loss we take monthly as a location. We will show them step by step what is expected and guide them throughout the process and explain the “why” and benefits of the project. We will have constant communication with leadership, SSRs & warehouse in order to see what is working.